Each Polycase customer’s project and environment is tailored to the appropriate electronic enclosure. There is no such thing as a universal enclosure, after all. The type of enclosure you need will be determined by your application. Some of the materials that could work well include polycarbonate, stainless steel, aluminum die casting, and extruded aluminum. Watertight extruded aluminum enclosure is a great alternative to printed circuit board enclosures (PCBs).

Is extruded aluminum available anywhere? Read on for more information

Why is aluminum extrusion one of the most reliable materials? A silvery-gray metal, aluminum is the world’s most abundant metal and is used in thousands of production processes. In either case, a die is used to shape a material, such as aluminum – or soap in this case – before the material is then extruded. Using a mold, aluminum is shaped or profiled to a desired shape.

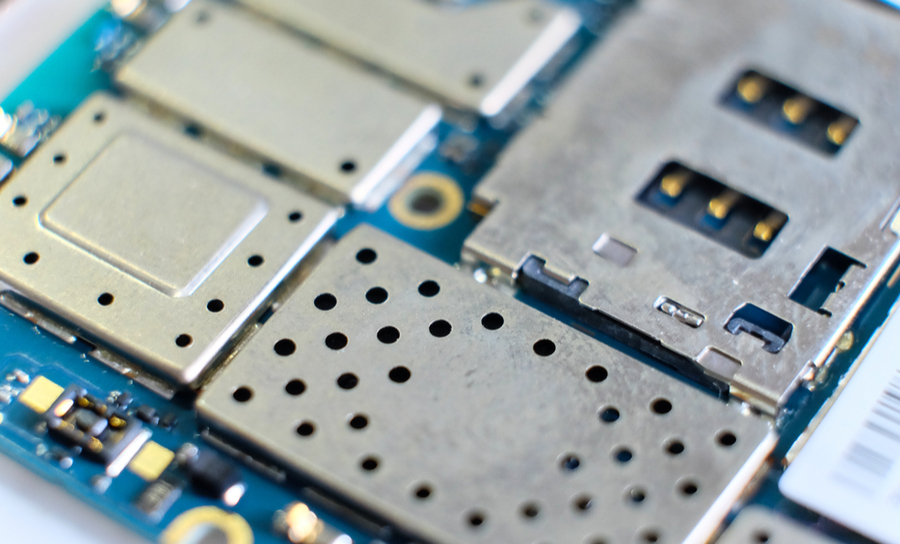

Compared to other manufacturing techniques, this has many advantages. A seamless, one-piece design and corrosion resistance are just a few of the benefits. It also has superior strength, a high strength-to-weight ratio (meaning it’s strong while still being relatively light), and an easier repair process since it is seamless. In order to protect PCB components, let’s explore some of these advantages.

They can be used at any temperature

All kinds of environments are suitable for extruded aluminum enclosures. As a result, the metal will stay solid in the sun, preventing the sun’s harsh rays from damaging your PCB components. For additional protection in outdoor environments, some extruded enclosures are equipped with watertight gaskets.

Intervention Can Be Prevented

The best way to prevent electromagnetic interference (EMI) and radio frequency interference (RFI) is to use aluminum. You may be familiar with aluminum foil covered televisions and radio antennas. Because aluminum is such an excellent signal absorber, it is used in these products. This will prevent them from reaching your internal components.

Components Within Are Protected

Enclosures made out of aluminum can also protect sensitive internal components from UV rays, water, dust, and other environmental factors. Because of their unique features, aluminum enclosures offer a better level of protection. Grooved outer edges promote heat dissipation, and a water-resistant gasket prevents dust and water from entering the device.

Their parts are durable

It is widely used because of its durability, among other things. With the extrusion process in combination with the material’s increased thickness and resistance to damage, warping or cracking is highly unlikely. Enclosures of ours are made of aluminum and diecast end caps.

They stand out thanks to their impressive features

Our electronic enclosures are crafted with exceptional care for the highest quality. We are known for the quality and dependability of our aluminum boxes. An integrated slot in the enclosure allows you to slide your PCB into it easily. Additionally, two points of entry provide access to the component inside each end cap.

Let Us Help

Is there anything we can help you with in terms of our aluminum enclosures? We at Polycase are always happy to help you find the most appropriate enclosure for your application. We also offer aluminum diecast enclosures that have excellent advantages along with aluminum extrusion housings. If you need assistance determining which option is right for your situation, please contact us.