High-quality industrial casting requires decades of experience and constant further development in order to meet the high demands of today’s technology. Dawangcasting.com distinctive know-how from mold construction to machined and surface-treated cast parts to complete production ensures a high level of technical sophistication, material and manufacturing quality.

From Small Quantities To Series Production

With a production of up to 50,000 pieces per year, mold production is a particularly economical alternative to the die casting process.

With annual quantities of a few 100 pieces, this technique is also ideal as an alternative to sand casting. Suitable casting materials are mainly aluminum and brass alloys.

The Casting Process

During the casting preparation, the permanent mold made of steel or gray cast iron is clamped in hydraulically operated machines. Then the mold halves and the necessary iron cores are pressed together hydraulically. The correct arrangement of the sprue and feeder system is decisive for the density, high strength and dimensional accuracy of the parts. Now the melt can be poured into the mold from above. Vent nozzles ensure that the air in the mold can escape. After the melt has solidified, the mold is opened, the part removed and the mold closed again. The casting process of further parts can now begin again.

The Casting Simulation

The casting technique should already be considered in the planning and the first design drafts for new products. In this way, it can be ensured at an early stage that the required material strength can be achieved with high cost efficiency and precisely adapted tools.

A casting simulation program, which is used for parts with extremely high load requirements, such as safety components, ensures the development of cast parts with special requirements in terms of material properties and casting technology. The software used for this works with the finite element method (FEM) , with which potential casting weak points in the part design can be identified in advance and thus excluded during casting .

The casting simulation is therefore used in particular before tool design for complex cast parts with 3D data provided by the client.

Even complex casting systems are optimized with this simulation method. By actively intervening in construction planning at an early stage, complex and expensive practical test series can be avoided and production costs can be reduced accordingly.

Read more, In combination with the decades of technical expertise of our casting specialists, this creates a supplementary step in the process chain that significantly increases the quality of the cast products.

At Rapid Prototyping Metal we concentrate on prototype investment casting and on the casting of small series. Mechanical post-processing and surface technology complete the offer.

Top Technology at Peak Times

For the production of metal prototypes in a quality similar to die-casting, a process has emerged that we prefer based on our experience and optimal customer benefit.

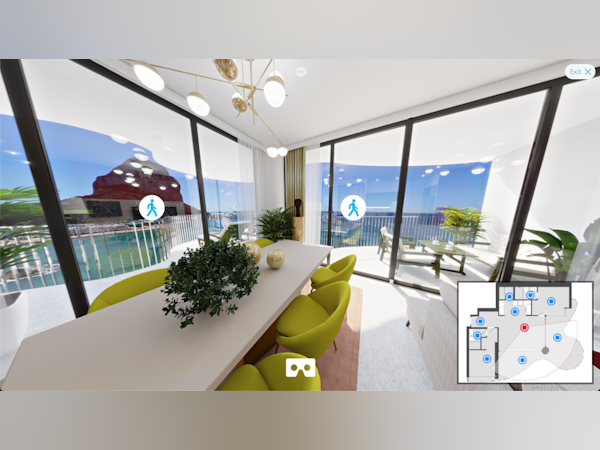

The Vacuum Differential Pressure Method

The VDD process is assigned to the investment casting and the plaster molding process. The process is computer-controlled in a system, with the prototypes being poured into ceramic »cuvettes«, similar to investment casting. The method enables the production of cast prototypes within a few days and is ideally suited for the individual production of functional and design prototypes as well as for the production of small series.

With the VDD process, we produce prototypes for components, which are then manufactured using the mass process pressure die casting and investment casting (to a lesser extent also for chill cast parts).

In the Beginning There is the Original Model

In the production of metal castings, too, the subsequent casting process begins with a master model (as in RP with plastic). If you keep the end product in front of your eyes and analyze customer needs and specific problems, logical steps result in completion.

- Creation of master models / lost models

- (Mold making)

- (Wax part casting)

- Wax tree construction

- Manufacture and fire ceramics

- Metal casting

- Rework

- Mechanical post-processing

- If necessary, surface treatment

So that the customer’s need for a tolerance according to VDG P690 A2 or A3 is satisfied, we largely manufacture our cast parts directly using lost models that we produce using 3D printing (components are produced using a Voxeljet 3D printing system). The steps of mold making and wax part casting are thus omitted and dimensional tolerances similar to die casting are possible.

Basic Data on Metal Casting

- Maximum component of size: 500 x 400 x 300 mm (LxWxH)

- Maximum pouring volume: 2.6 to 3 liters

- Minimum wall thickness aluminum: 1mm

- Production time depending on the number of pieces: 1 to 3 weeks for approx. 3 to 5 pieces

- Alloys: aluminum, zinc

- Dimensional accuracy: Tolerance class A1 according to VDG leaflet P690 achievable – depending on the process for the lost models and the dimension / size of the components

Mechanical Post-Processing

The VDD process with its high achievable dimensional tolerance and very good surface quality is at the forefront of common casting processes. In the case of 1zu1 prototypen, we carry out the mechanical post-processing of the cast parts on five-axis milling machines and CNC lathes.