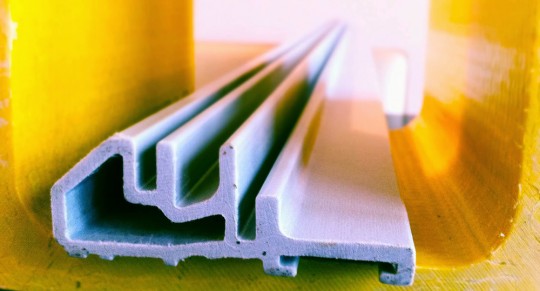

Fiber-reinforced plastics, also known as fiber-reinforced polymers (FRP), are manufactured by extrusion, a process that converts reinforced fibers into liquid resin.

In the pultrusion process, fiberglass rovings are pulled through a resin bath or resin impregnator, which completely saturates the fiber reinforcements, allowing them to be produced continuously and efficiently. The Pultrusion die consists of heated steel and resin, which hardens into strong, lightweight end products that follow the shape of the die.

The Process of Extrusion

As part geometry can vary, the design of the extrusion machine can also vary. In order to create a FRP profile, two basic types of pulling systems are employed: reciprocating (man over man), and continuous (cat track).

The fiber reinforcement rovings are positioned on the creels, and they are continuously fed onto the guide plate. It is vital that the fiber reinforcements are positioned correctly within the composite to ensure strength and quality.

Fiber reinforcements are thoroughly saturated in epoxy, polyurethane, polyester or vinyl ester resin baths as a result of the resin impregnator’s optimal design. A composite can contain fillers and other additives including colors, fire inhibitors, and UV radiation retardants to increase its durability.

A performer is used to squeeze out excess resin from the reinforcements and organize them into the correct shape after they exit the resin impregnator. The use of continuous strand materials and protective surface coatings are common additives in this process to make the final product stronger, corrosion-resistant, and better finished.

A steel die polymerizes the resin impregnated fiber after it has been placed in the resin. In order to solidify the thermosetting resin, the die is heated to a consistent temperature.

After the hardened FRP is pulled towards the saw, it is accurately cut to the required length by the pulling system. By using urethane pull locks, the pulling system ensures that cured profiles are not cracked, deformed, or distorted.

The Following Industries use Products made with this Technology:

- Construction of livestock facilities, chemical plants, etc. requiring chemically resistant slatted floors with enhanced strength properties; for the manufacture of slatted floors used in agricultural and chemical industries;

- It is used in the construction industry for the manufacture of glass-fiber reinforcement, profiles, carcasses and rigidening bars for PVC windows;

- Components of aircraft structures manufactured in the aerospace industry;

- Construction of tents and hovels, skis, ski poles, golf course flagsticks, etc. in the sports and tourism industries.;

- As a supplier of dielectric structures, fiberglass rods used to make composite insulators and as support structures for signaling blocks, and fiberglass profiles used to assemble transformers and electric motors in electrical power engineering;

- Putting grains of long-fiber molding material (LLM) into commercial production as raw materials for subsequently producing structures and products that are stronger and chemically more efficient;

- Manufacturing structural, rigid, and lightweight parts in the automotive industry;

- Chemical, dielectric, and strength stability are high standards required for many industrial and plant mechanisms, structures, and materials.