You have worked hard to plan, design, and research your new electrical gadget or product. Your design will be put into action by the printed circuit board (PCB). What is the process for working with the actual PCB design?

It’s messy, expensive, and hazardous to build your own PCB, even though there are DIY PCB tinkerers and blogs. Having a PCB professionally manufactured by an experienced manufacturer and working with that manufacturer will be easier and more reliable. With so many PCB manufacturers on the market, it may be challenging to choose the best. While some PCB manufacturers may be better suited for small firms and inventors, others may be better suited for large companies with electrical engineers.

Regardless of why you are designing a PCB, consider these factors when choosing a China PCB manufacturer. You can save money, time, and ensure that you won’t end up with defective products when you choose the right product.

It’s Important To Think About Scale

How many PCBs will you need is the first question you should answer. As a PCB hobbyist, you should find PCB manufacturers whose interests match yours. It’s best to choose PCB manufacturers who offer simple solutions, PCB design software that’s easy to use, and tutorial videos. As a result, you will be able to stay on top of the process, and build a solid foundation in PCB design. Make sure you check the requirements for minimum orders when looking for PCB manufacturers. When you are a PCB designer at home, you likely won’t order more than one or two boards per order. Hence, you should avoid companies that require a minimum order.

In case your business requires large orders to be fulfilled, you’ll need a PCB design firm that can handle large orders quickly. By checking their bulk pricing, you can make sure the company can meet your demand.

Make Wise Investments

Keep your budget in mind when designing your PCB. In more elaborate projects, a Bill of Materials will specify how much equipment to buy and what kind in order to complete the project. Once that is done, the manufacturer and you will know how much money is needed for the project.

You’ll also have to pay more if you need a multilayer PCB. It depends on your application whether a multilayer PCB is beneficial or necessary. The size of a multilayer PCB allows you to add more components since it has a larger surface area. If you have a circuit board with more complex components, you will want to use multiple layers to avoid overcrowding. During overcrowding and overheating, short circuits can occur.

By knowing what materials and layers your PCB design requires, you can compare prices between PCB manufacturers. Advanced Circuits, for example, offers exclusive deals on their two- and four-layer PCBs, making it possible to afford high-powered technology.

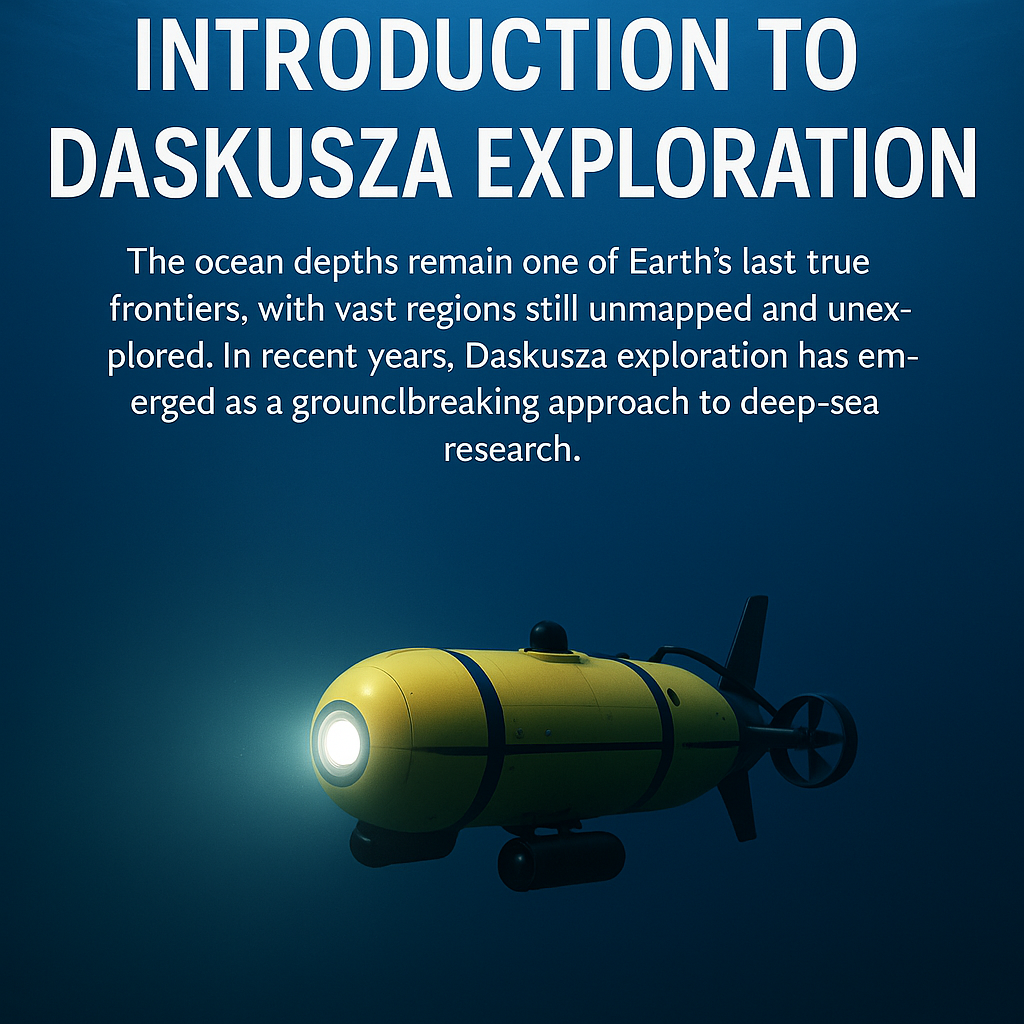

You Need to Know Right Away

The manufacturer should be able to get the work done as quickly as possible if you’re working on a tight deadline. A more complex PCB design is likely to take longer to produce and deliver than a simpler prototype. From three to fourteen days, waiting times can vary depending on the company. The third largest U.S. PCB manufacturer, Advanced Circuits, offers same-day turn-around on certain orders. Offering same-day turn-around on certain orders, Advanced Circuits is the third largest U.S. PCB manufacturer.

Reputation and its Importance

After putting so much time and effort into a PCB design, poor quality production is the last thing you want. Your PCB shouldn’t arrive and you discover the holes weren’t drilled correctly or the dimensions have been mismeasured. Therefore, you should check the reputation of PCB manufacturers before sending them your project. A good indicator of quality is to work with other large companies.

The Department of Defense, for instance, approves Advanced Circuits for manufacturing contracts for federal government agencies. Trusting Advanced Circuits with your PCB design means you will receive a high standard of quality and service.