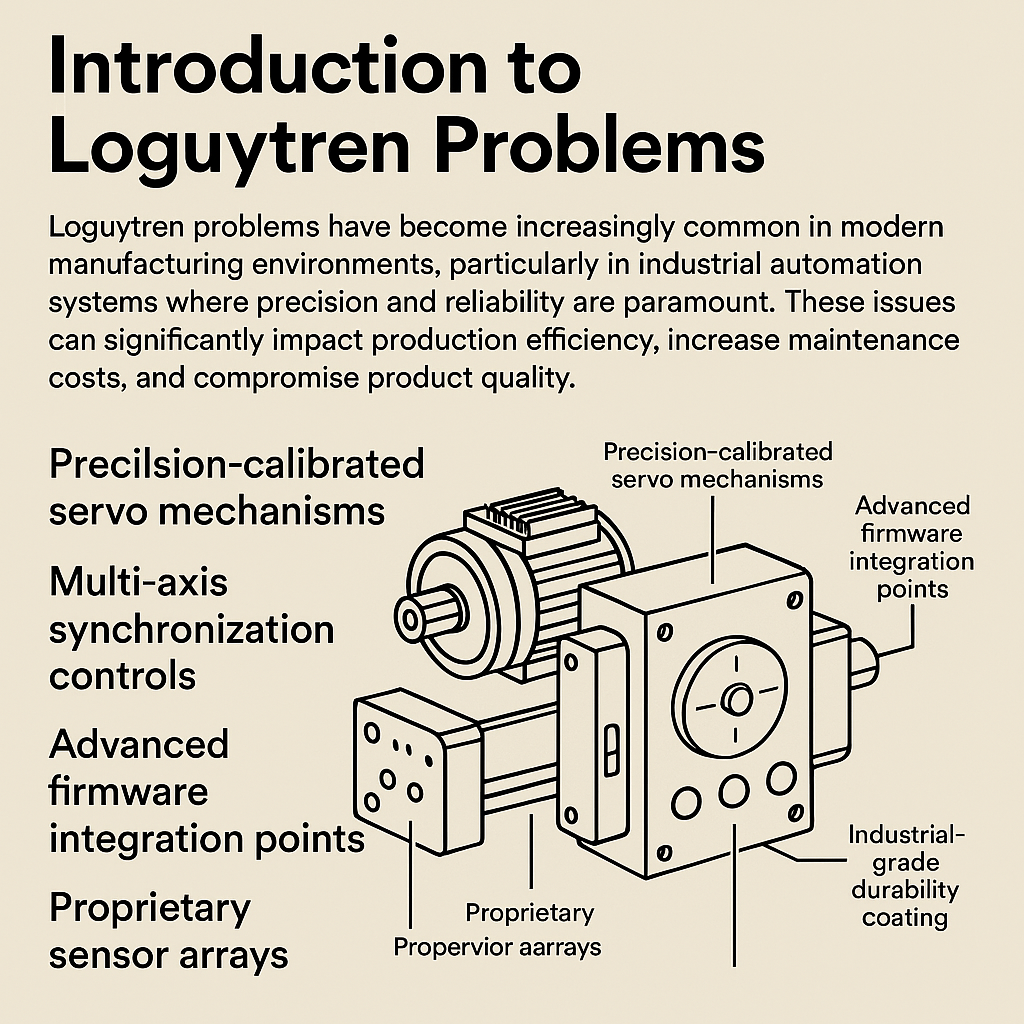

Introduction to Loguytren Problems

Loguytren problems have become increasingly common in modern manufacturing environments, particularly in industrial automation systems where precision and reliability are paramount. These issues can significantly impact production efficiency, increase maintenance costs, and compromise product quality. This comprehensive guide explores the various aspects of loguytren problems, their root causes, effective troubleshooting methods, and prevention strategies to maintain optimal system performance.

What Exactly Are Loguytren Components?

Before diving into the problems, it’s important to understand what loguytren components are. Loguytren refers to a specialized class of mechanical-electronic interface systems used primarily in automated manufacturing equipment. These systems typically consist of:

- Precision-calibrated servo mechanisms

- Multi-axis synchronization controls

- Advanced firmware integration points

- Proprietary sensor arrays

- Industrial-grade durability coatings

First developed in the early 2000s, loguytren technology revolutionized how automated systems handle precision tasks under variable conditions. Their integration into manufacturing lines has allowed for unprecedented accuracy in processes ranging from microchip fabrication to automotive assembly.

Common Loguytren Problems and Their Causes

Loguytren problems typically manifest in several distinct ways, each with specific underlying causes. Understanding these issues is the first step toward effective troubleshooting.

Calibration Drift

One of the most frequently encountered loguytren problems involves calibration drift. This occurs when the precision alignment of components gradually shifts over time, resulting in:

- Decreased production accuracy

- Inconsistent product specifications

- Increased rejection rates

- Unexpected system faults

Calibration drift is commonly caused by:

- Thermal expansion and contraction cycles

- Microscopic vibration displacement

- Natural wear on mechanical interfaces

- Electromagnetic interference patterns

According to a 2023 industry survey by Manufacturing Technology Quarterly, approximately 37% of facilities using loguytren systems reported significant calibration issues within 18 months of installation.

Firmware Integration Failures

Modern loguytren components rely heavily on proprietary firmware that must seamlessly integrate with broader control systems. Integration failures represent about 28% of all reported loguytren problems and typically manifest as:

- Unexpected system crashes

- Command execution delays

- Data reporting inconsistencies

- Communication protocol conflicts

These integration issues most commonly occur after system updates or when incorporating new equipment into existing production lines.

Sensor Degradation

The high-precision sensors integral to loguytren functionality often experience degradation over time. This sensor deterioration accounts for approximately 22% of loguytren problems, according to maintenance records from major manufacturing facilities. Signs of sensor degradation include:

- Intermittent reading errors

- Increased false positives in quality control

- Gradual decline in measurement precision

- Inconsistent response times to environmental changes

Diagnosing Loguytren Problems Effectively

Proper diagnosis is crucial before attempting any repairs or adjustments to loguytren systems. The diagnostic process should follow a structured approach:

Step 1: Data Collection and Analysis

Begin by collecting comprehensive operational data, including:

- Error logs and fault histories

- Production quality metrics over time

- Environmental condition records

- Maintenance history documentation

Modern diagnostic tools often incorporate AI-assisted analysis to identify patterns that might escape human observation. For example, the LoguTech Diagnostic Suite can analyze thousands of operational hours to identify subtle precursors to common loguytren problems.

Step 2: Isolation Testing

Once potential issues are identified, isolation testing helps pinpoint specific components causing trouble:

- Segment the system into functional zones

- Perform controlled tests on individual components

- Utilize specialized diagnostic equipment

- Document all responses and behaviors

Step 3: Environmental Assessment

Many loguytren problems stem from environmental factors, making assessment critical:

- Temperature and humidity fluctuations

- Electromagnetic field mapping

- Vibration spectrum analysis

- Particulate contamination measurement

Advanced Solutions for Persistent Loguytren Problems

When facing particularly challenging loguytren problems, advanced solutions may be necessary. These approaches have proven effective in resolving complex issues:

Firmware Regression Testing

For integration-related loguytren problems, regression testing often reveals compatibility issues:

- Roll back to previous stable firmware versions

- Gradually reintroduce updates while monitoring performance

- Create isolated test environments for new integrations

- Document all configuration changes meticulously

Case Study: A semiconductor manufacturer in Taiwan reduced loguytren-related downtime by 73% after implementing a comprehensive firmware regression testing protocol that identified conflicts between their control system updates and proprietary loguytren firmware.

Precision Recalibration Protocols

Advanced recalibration goes beyond standard maintenance procedures:

- Laser-guided alignment verification

- Temperature-controlled calibration environments

- Vibration-isolated adjustment procedures

- Statistical process control implementation

These methods have been shown to extend intervals between calibration requirements by up to 300% in high-precision applications.

Sensor Array Optimization

Rather than simply replacing degraded sensors, optimization involves:

- Redundancy implementation in critical measurement points

- Environmental shielding enhancements

- Signal processing algorithm refinements

- Adaptive filtering implementation

Preventive Maintenance to Avoid Loguytren Problems

The most cost-effective approach to loguytren problems is prevention through scheduled maintenance. An effective preventive maintenance program should include:

Regular Inspection Schedules

- Daily visual inspections of critical components

- Weekly performance baseline measurements

- Monthly comprehensive diagnostic scans

- Quarterly professional assessment and certification

Environmental Control Measures

- Temperature and humidity stabilization systems

- Electromagnetic shielding implementation

- Vibration dampening foundations

- Clean room protocols for sensitive installations

Staff Training and Certification

- Specialized training for maintenance personnel

- Certification programs for operators

- Regular knowledge refresher courses

- Documented competency verification

Future Developments in Loguytren Technology

The field of loguytren technology continues to evolve, with several promising developments that may address current problems:

- Self-calibrating systems using machine learning algorithms

- Remote diagnostic capabilities via secure cloud connections

- Predictive maintenance AI that identifies potential issues before they manifest

- Materials science advancements for more durable components

Conclusion: A Strategic Approach to Managing Loguytren Problems

Effectively managing loguytren problems requires a strategic approach combining thorough diagnosis, appropriate solutions, and preventive maintenance. By understanding the common issues that affect these sophisticated systems and implementing structured protocols for their maintenance, manufacturers can significantly reduce downtime, improve product quality, and extend the operational lifespan of their equipment.

As manufacturing continues to embrace automation and precision technologies, the importance of properly addressing loguytren problems will only increase. Organizations that develop expertise in this area gain a competitive advantage through improved reliability and reduced operational costs.